The basic working principle of manual gearbox is popularized

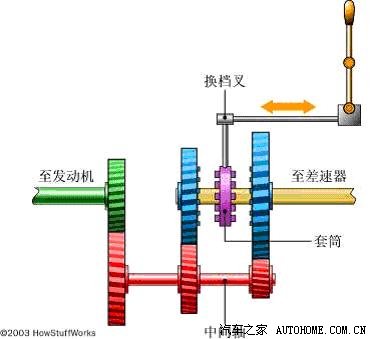

In order to better understand the working principle of the gearbox, let’s first look at a simple model of a 2-speed gearbox and see how the parts cooperate:

The input shaft (green) is connected to the engine through a clutch, and the shaft and the upper gear are a part.

Simple model of gearbox

The shaft and the gear (red) are called intermediate shafts. They rotate together. The rotation of the shaft (green) drives the rotation of the intermediate shaft through the meshing gear. At this time, the intermediate shaft can transmit the power of the engine.

The shaft (yellow) is a spline shaft, which is directly connected with the driving shaft and drives the car through the differential. When the wheel rotates, it rotates with the spline shaft.

The gear (blue) rotates freely on the spline shaft. When the engine is stopped, but the vehicle is still in motion, the gear (blue) and the intermediate shaft are at rest, while the spline shaft still rotates with the wheel.

The gear (blue) and the spline shaft are connected by a sleeve, which can rotate with the spline shaft and slide freely on the spline shaft to engage the gear (blue).

When engaged in 1st gear, the sleeve engages with the right gear (blue).

As shown in the above figure, the input shaft (green) drives the intermediate shaft, and the intermediate shaft drives the right gear (blue), which is connected with the spline shaft through the sleeve to transfer energy to the drive shaft. At the same time, the left gear (blue) is also rotating, but it has no influence on the spline shaft because it is not engaged with the sleeve.

When the sleeve is between two gears, the gearbox is in neutral position. Both gears rotate freely on the spline shaft, and the speed is determined by the speed ratio between the gear on the intermediate shaft and the gear (blue).

5-speed manual transmission model

Note that reverse gear is simply achieved by adding a pinion.

The shift lever is connected with three shift forks through three connecting rods. There is a rotation point in the middle of the shift lever. When you shift into the first gear, you actually push the connecting rod and the shift fork in the opposite direction.

When you move the shift lever left and right, you are actually choosing different shift forks (different sleeves); When moving back and forth, you choose different gears (blue).

synchronizer

Synchronization is to make a frictional contact between the teeth on the sleeve and the gear (blue) before meshing.

The conical protrusion on the gear (blue) just snaps into the conical notch of the sleeve, and the friction between them makes the sleeve and the gear (blue) synchronize, and the outer part of the sleeve slides and meshes with the gear.

Sport 6 speed manual transmission

Automobile manufacturers have their own ways to make gearboxes. Here is a basic concept! (User/Liushui)